Do you have ac motors in your facility?

Do these motors need a variable output?

Do you use mechanical means to vary the output?

If you anwsered yes to these questions, you need to install variable frequency drives on these ac motors.

If you are not using VFD’s you are wasting energy and throwing money out the window.

In the United States 50% of the total electrical energy generated is consumed by rotating equipment. 65% of this total is consumed by centrifugal or flow related applications such as fans, blowers, compressors, and pumps according to current estimates. Variable speed drive technology offers a cost-effective method to match driver speed to load demands and represents a state-of-the-art opportunity to reduce operating costs and improve overall productivity.

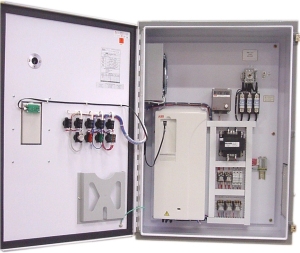

Power Formers Engineers is an OEM that custom packages, integrates and engineers AC Variable Frequency Drives (VFD), DC Variable Speed Drives (VSD) and AC Drive Controllers. Our drive systems integrate top of the line manufacturers, like ABB, Emerson (Control Techniques & Saftronics / Fincor), Siemens and WEG to name a few. Our added value custom drive packages are built to your specifications for your application.

What is a Variable Frequency Drive?

You can divide the world of electronic motor drives into two categories: AC and DC, a motor drive controls the speed, torque, direction and resulting horsepower of a motor. AC drives control AC induction motors. DC drives typically controls a shunt wound DC motor, which has separate armature and field circuits.

Motor drives are also known as DC Drives, AC Drives, SCR Drives (Silicon Controlled Rectifier Drive), Variable Frequency Drives, Variable Speed Drives, Adjustable Speed Drives, Electric Motor Drives, Electronic Motor Drives, AC Motor Controllers, AC Inverters, Pulse Width Modulation (PWM) Drives and a few other names.

Which Drive is Right for your Application?

The AC Variable Frequency Drive market is huge, due to the great advances in highly reliable AC power electronics and high power microprocessors. The Flux Vector AC Drive for example, can compete on an application basis that DC Drives would in earlier years be required.

Even though AC Variable Frequency Drives are readily replacing DC Drives and motors, there is still a large base of DC equipment that has to be supported by experienced technicians. Joliet Technologies believes that by not abandoning the DC market we can better serve our customer base demands. For example, older machines with multiple exciting DC Analog drives and motors may be a great candidate for retrofitting newer digital DC drive equipment. Saving cost and down time.

If your needs are much simpler and speed control is not part of the work scope. Joliet Technologies can provide Custom AC Drive Controllers consisting of contactors, starters, relays, pushbuttons and PLCs. Our engineers can provide all PLC and Peripheral Programming needs. Panels can be designed by another OEM or we can help with engineering to specifications provided.

| DC Variable Speed Drive | |

| PROS | CONS |

| Torque control and limiting | Brush life commutation maintenance. |

| Wide speed range (under 5000 RPM) | Motor high speed limit (high speeds use expensive gear boxes) |

| Trimming capabilities | Expensive large HP motors |

| Constant HP capabilities | Power system harmonics |

| True 4-quadrant regenerative energy conversion | NA |

| Few distance limitations | NA |

| Cost (especially single phase sizes) | NA |

| AC Variable Frequency Drive | |

| PROS | CONS |

| Improved efficiency | Distance limitations |

| Low motor maintenance | Large system designs (high HP drive foot prints) |

| Tight control | Cost (encoder feedback) |

| Digital control | Expensive regenerative braking |

| High speed capabilities | Power system harmonics |

| Reversing capability without extra power elements | NA |

Power Formers Engineers Custom Panel Shop and On Site Retrofit Benefits

We have the experience and know how to provide you with the best drive for your application. Joliet Technologies can evaluate your current equipment and recommend either a Retro-Fit or System Replacement. Feel free to contact us with any drive questions you may have.

Joliet Technologies is dedicated to provide the highest quality equipment and service. This is why we started this company. With our experience, expertise and commitment, you will be completely satisfied with our workmanship and our work ethic. All work is performed following our Quality Assurance System (based on the ISO9001:2008 Standard), assuring you the highest quality.

From system integration to panel fabrication Joliet Technologies provides quality systems and custom control panels for new applications or system upgrades, all in a timely fashion, and at competitive rates.

Do you know how to maintain a VFD? Doing so is easier than you might think. By integrating some simple, logical steps into your preventative maintenance program, you can ensure your drives provide many years of trouble-free service.